OMET: new boundaries in the world of interfolded

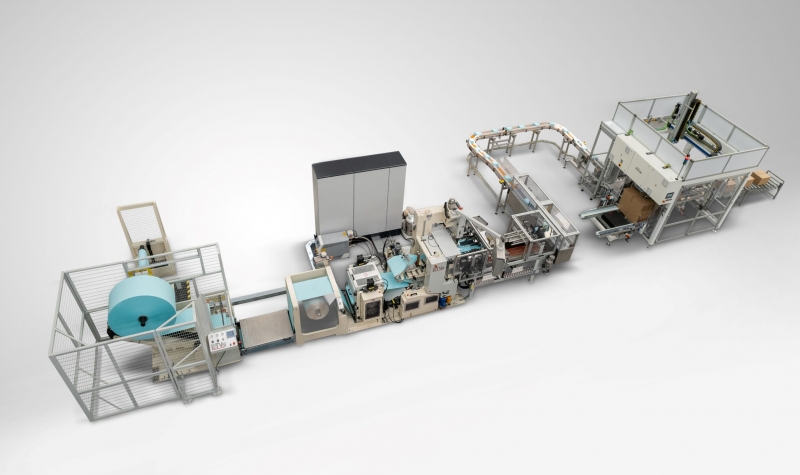

After setting new technological standards in the world of interfolded products with the ASV Line, OMET introduces a new and high-performance interfolded line for multi-panel products with Z and W folds. The new machine is the ASZ Line.

OMET’s ASV Line has established itself as a benchmark in the field of automatic interfolding, setting high standards for the production of a wide range of products, including interfolded towels, kitchen towels, facial tissue and interfolded toilet paper. Modular and with a user-friendly design, this highly productive machine offers various configurations and different types of folds (V, W and Multifold), adapting to the unique needs of each customer.

With the launch of the new and innovative ASZ Line, OMET further expands the capabilities of its lines. This new machine handles two types of folds: Z-Fold and W-Fold. Equipped with a completely new interfolded head and carefully designed for Z-fold end products, the ASZ Line also combines extensive modularity, ease of use and high performance in terms of product quality and quantity, ensuring high productivity.

The new ASZ Line features several distinctive characteristics, including the quick changeover from 3-panel to 4-panel product. This functionality allows the operator to select the desired product while the machine automatically moves the transfer roller to the correct working position. Machine management is made extremely simple thanks to automatic systems that facilitate the transfer of cut sheets between the various rolls, adapting to the machine’s speed to ensure precision and reliability even in the presence of variations in paper characteristics. Additionally, the use of vacuum folding rolls, developed based on experience gained with the ASV Line, ensures optimal fold quality and significantly reduces maintenance costs compared to other types of rolls used for Z-fold. Finally, optimal accessibility to all parts of the ASZ eliminates the need for intervention by specialized technicians and reduces downtime after maintenance, ensuring optimal and continuous operation and contributing to a significant reduction in service costs and times.

The new ASZ Line features several distinctive characteristics, including the quick changeover from 3-panel to 4-panel product. This functionality allows the operator to select the desired product while the machine automatically moves the transfer roller to the correct working position. Machine management is made extremely simple thanks to automatic systems that facilitate the transfer of cut sheets between the various rolls, adapting to the machine’s speed to ensure precision and reliability even in the presence of variations in paper characteristics. Additionally, the use of vacuum folding rolls, developed based on experience gained with the ASV Line, ensures optimal fold quality and significantly reduces maintenance costs compared to other types of rolls used for Z-fold. Finally, optimal accessibility to all parts of the ASZ eliminates the need for intervention by specialized technicians and reduces downtime after maintenance, ensuring optimal and continuous operation and contributing to a significant reduction in service costs and times.

OMET’s interfolding lines stand out for their commitment to sustainability. Particular attention has been paid to the design of vacuum ducts to minimize pressure losses and optimize airflow. Through targeted studies, significant improvements have been achieved in terms of energy savings and efficiency of the suction system, slowing down gas speeds and reducing differential pressures in environments where gas pressure is lower than atmospheric pressure.

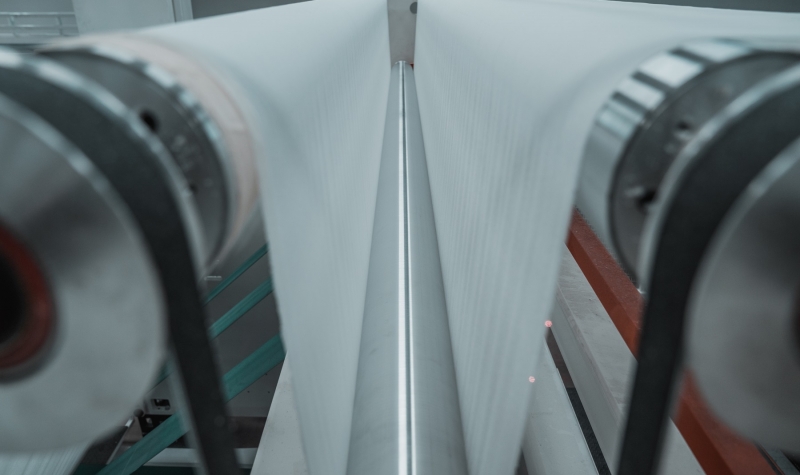

OMET interfolding lines now offer the possibility of achieving a paper width of up to 5000 mm, while maintaining high levels of speed and quality of the final product.

The paper reel is cut in the center and folded in two. Thanks to a central support that limits the bending of the rolls, product quality is guaranteed even on reels up to 5000 mm wide.

The paper reel is cut in the center and folded in two. Thanks to a central support that limits the bending of the rolls, product quality is guaranteed even on reels up to 5000 mm wide.

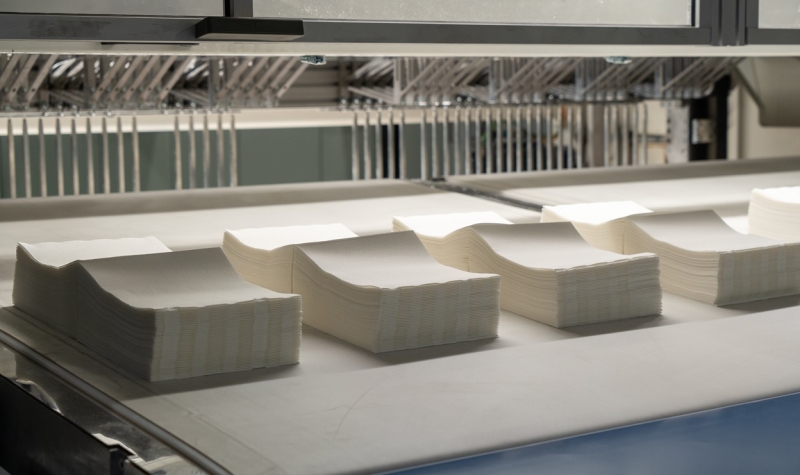

The patented technology includes a double servo-controlled counting and automatic separation system, coupled with a double conveyor belt, which ensures accuracy in sheet counting and a continuous workflow. It is possible to produce different sheet counts simultaneously for each forming zone, thus increasing production flexibility. The evacuation of logs is carried out through two independent belts with different configurations, reducing evacuation times and ensuring high production speed. This innovation can be easily implemented on both the ASV Line and the new ASZ Line.

In conclusion, with the new ASZ Line and the ability to achieve a wider paper width, OMET takes a significant step forward in advancing interfolding technologies, offering cutting-edge solutions for more efficient and sustainable production, adapting to the changing needs of the market, and reducing maintenance times and costs.

|

|

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group