OMET: Innovation, Change and Sustainability

OMET, renowned for its high technological efficiency and continuous pursuit of innovative solutions, has taken significant steps to enhance customer benefits through a global optimization approach in its production process.

At the core of all OMET production lines lies an exceptionally high technological level, achieved through constant research and development of innovative solutions. This cutting-edge approach has enabled OMET to stay ahead of competitors and meet the demands of the most discerning customers.

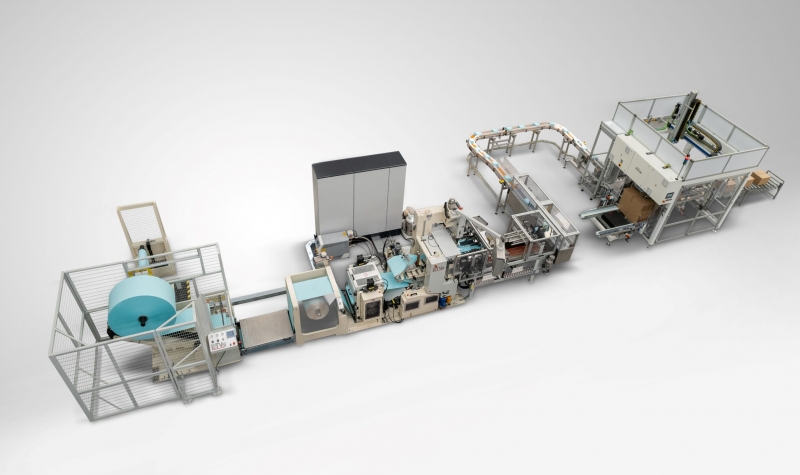

Envisioning an efficient production process from the outset has become a usual perspective. OMET understands that to ensure long-term sustainability and a lasting competitive advantage, it is crucial not only to optimize individual solutions but also to view the entire production process as an integrated system.

Envisioning an efficient production process from the outset has become a usual perspective. OMET understands that to ensure long-term sustainability and a lasting competitive advantage, it is crucial not only to optimize individual solutions but also to view the entire production process as an integrated system.

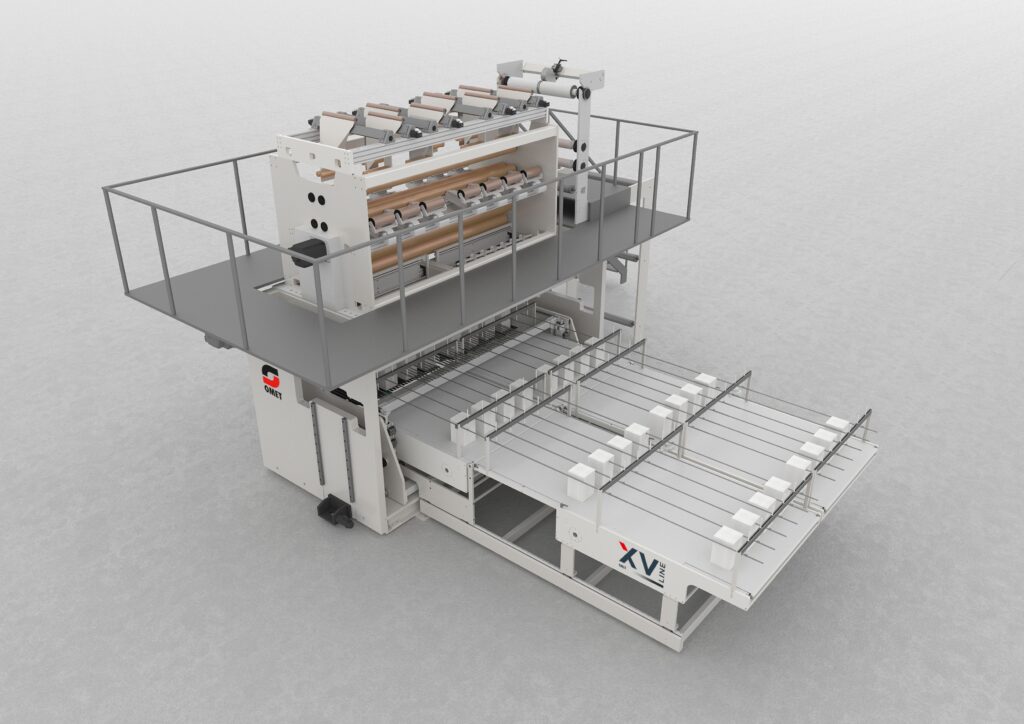

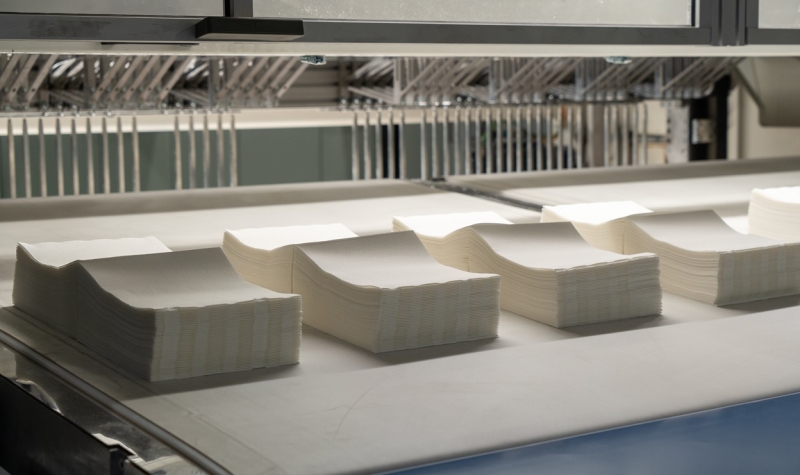

A pillar of OMET’s strategy is modularity. Key components and modules of its production lines are designed for reusability across multiple processes, reducing resource wastage and providing customers with tailored solutions that optimize efficiency and productivity.

The successful implementation of the “Lean” philosophy in its production processes has also been pivotal. This philosophy aims to eliminate waste, minimize space, and utilize resources to maximize overall efficiency. With the “Lean” approach, OMET has achieved highly efficient processes, enhancing performance and reducing overall costs.

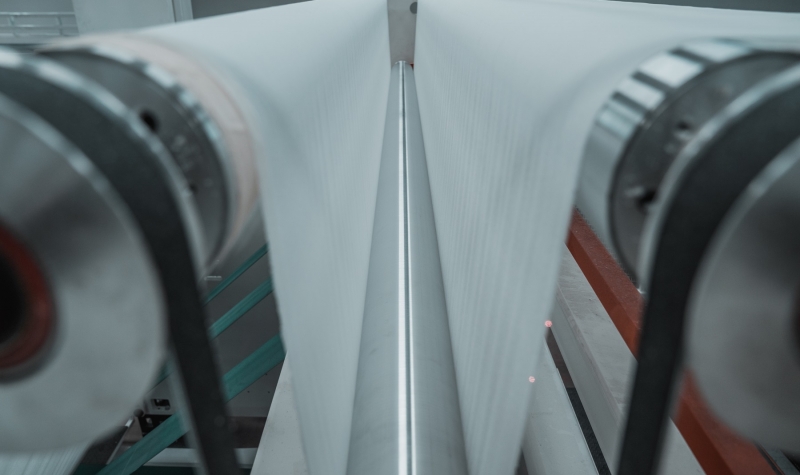

OMET has also embraced various advanced digital technologies, including the “Digital Twin,” a virtual replica of a physical system used to test machine functionalities and components before actual construction. This approach has led to zero waste associated with these activities, reducing environmental impact, and further enhancing the production process. The orientation towards producing wide-web lines has been another choice made by OMET to minimize the need for cutting, rewinding, and storage operations, allowing customers to have shorter and more sustainable transformation processes and thereby reducing energy consumption, space, and transportation costs.

OMET has also embraced various advanced digital technologies, including the “Digital Twin,” a virtual replica of a physical system used to test machine functionalities and components before actual construction. This approach has led to zero waste associated with these activities, reducing environmental impact, and further enhancing the production process. The orientation towards producing wide-web lines has been another choice made by OMET to minimize the need for cutting, rewinding, and storage operations, allowing customers to have shorter and more sustainable transformation processes and thereby reducing energy consumption, space, and transportation costs.

Thanks to a recent partnership between OMET and PRB INNOVATION, an Italian company specializing in end-of-line machines and based in Imola (Emilia-Romagna), OMET is working to optimize resources and reduce waste through the integration of all machines forming the production line, from the reel to the pallet. This integration aims to simplify supply chain management, facilitate information exchange between different processes, and improve overall social efficiency.

Finally, digitalization has played a fundamental role in optimizing production processes. In this context, OMET has developed SFERA, an Industrial AIoT (Artificial Intelligence Internet of Things) platform for managing and monitoring its machines and production lines. SFERA integrates various functionalities, including efficiency analysis, bottleneck identification, process telematics and black box, energy consumption, and preventive and predictive maintenance. This platform enables the company to gain a comprehensive and detailed view of its machines’ performance and make informed decisions to further enhance efficiency and sustainability in its production processes.

Finally, digitalization has played a fundamental role in optimizing production processes. In this context, OMET has developed SFERA, an Industrial AIoT (Artificial Intelligence Internet of Things) platform for managing and monitoring its machines and production lines. SFERA integrates various functionalities, including efficiency analysis, bottleneck identification, process telematics and black box, energy consumption, and preventive and predictive maintenance. This platform enables the company to gain a comprehensive and detailed view of its machines’ performance and make informed decisions to further enhance efficiency and sustainability in its production processes.

In conclusion, OMET has demonstrated a steadfast commitment to efficiency, both in optimizing the production process of its machines and in the creation of its products. Through the adoption of innovative solutions, the “Lean” philosophy, and the integration of advanced digital technologies, the company has made significant strides towards the creation of more efficient, sustainable, and advantageous processes, with the aim of empowering its customers to thrive in a competitive market.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group