Packages Convertors Ltd: innovation and quality in tissue converting

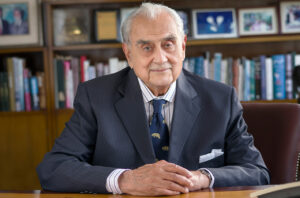

Packages Convertors Ltd, a wholly owned subsidiary of the Packages Group, was founded in the 1950s and is today one of the key players in Pakistan’s packaging and tissue product market. To support its growth and ensure increasingly high-quality standards, the company recently chose to invest in OMET technology. In this interview, Wasik Ali Syed shares the reasons behind this strategic investment, highlighting the tangible benefits it has brought. He also retraces the company’s evolution, explaining its production structure and future development plans.

How was Packages Limited founded and how has its governance evolved over time?

Packages Limited was established in 1956 in Lahore, Pakistan, as a joint venture between Pakistan’s Ali Group and Sweden’s Åkerlund & Rausing, initiated by Pakistani entrepreneur and philanthropist Syed Babar Ali. The initial aim was to produce packaging materials for Treet Corporation’s razor blades—owned by the family—and to reduce dependence on imported packaging. Today, Packages Limited is listed on the Pakistan Stock Exchange, with Syed Hyder Ali serving as the current Managing Director and CEO. Packages Convertors Ltd is a fully owned subsidiary of the Packages Group.

What have been the key milestones in your company’s development, and what are your main markets and products today?

What have been the key milestones in your company’s development, and what are your main markets and products today?

Over the years, Packages Limited has diversified and expanded its business. Between the 1970s and 1990s, it added flexible packaging, corrugated boxes, and tissue products to its portfolio. In 2005, it restructured operations and launched the Packages Mall. It later expanded regionally with Packages Lanka in Sri Lanka and Flexible Packages Convertors in South Africa. In recent years, it has invested in sustainable packaging and digital printing, boosting its export business.

Today, the company supplies folding cartons, flexible packaging, corrugated boxes, tissue products (under the Rose Petal brand), and paper and board. It operates mainly in Pakistan and counts global clients such as Unilever, Nestlé, and PepsiCo. Export markets include the Middle East, Africa, Sri Lanka, and South Asia.

What is the current size of your group and where do you operate?

The group currently employs over 4,000 people and operates several production plants in Pakistan, primarily in Lahore and Kasur. Internationally, we are present in Canada, Sri Lanka, the UAE, and South Africa. Our revenue breakdown is: 46% from flexible packaging, 25% from folding cartons, and 29% from consumer products.

How is your production organized?

Our operations are structured into five main divisions: Paper & Board, Folding Cartons, Flexible Packaging, Corrugated Packaging, and Tissue & Consumer Products. Most of our production activities are based in Lahore and Kasur.

How did you discover OMET, and what led you to choose its technology?

We came across OMET at international trade fairs such as MIAC and It’s Tissue. OMET’s reputation for innovation and quality in the tissue sector played a key role in our decision. This investment is part of our ongoing commitment to technological advancement and operational excellence, aimed at increasing efficiency and product quality in our tissue line.

Which OMET machine did you choose, and why? How satisfied are you with the results?

We selected the OMET TV503 Line for its advanced automation, high-speed performance, and flexibility in producing various napkin formats. The TV503 runs at up to 600 m/min, and we’ve been using it to its full potential for over five years. It enables precise adjustments and remote monitoring, minimizing setup time and downtime.

We evaluated other options but found OMET’s technology best suited our needs thanks to its modular design, ease of maintenance, and integration with downstream packaging solutions. We are fully satisfied with the machine’s performance and user-friendliness, but most of all with the technical support—both in-person and remote—which ensures optimal efficiency at all times.

How has this investment supported your business growth, and what tissue products are most strategic for you?

How has this investment supported your business growth, and what tissue products are most strategic for you?

The OMET TV503 Line has had a strategic impact on our portfolio, especially for our Rose Petal brand. This technology has enabled us to boost production capacity and improve product quality—with more precise folding and superior print registration.

Increased productivity, faster changeovers, and automation have helped us reduce costs and lead times, enhancing service for our Away-From-Home (AFH) customers. We produce customized table and cocktail napkins, which are key to strengthening our position in both the retail and HoReCa channels, reinforcing the premium image of Rose Petal.

How do you position yourselves in the market, and what growth outlook do you foresee?

We are recognized leaders in the packaging and tissue sector in Pakistan, known for our focus on quality, innovation, and sustainability. We are trusted suppliers to major global brands such as Nestlé, McDonald’s, KFC, Subway, and PepsiCo.

Looking ahead, we anticipate growth driven by rising demand for sustainable products, the e-commerce boom, and growing public awareness around hygiene.

What innovation and investment areas are you focusing on to respond to market evolution?

Our investment priorities include the development of eco-friendly solutions, advanced automation, digital printing, human resources training, R&D, and energy-saving technologies. We believe the market is moving toward more personalized, sustainable, and high-value products.

Are there other projects or initiatives you consider particularly strategic for your company’s development?

We’ve launched continuous training programs, foster a corporate culture centered on collaboration and safety, and are investing in the modernization of our production facilities. We are committed to sustainability projects to reduce environmental impact and to communication initiatives aimed at strengthening our brand. In addition, we continue to develop new, innovative packaging solutions to meet the evolving needs of international markets.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group